Working Principle of Vortex Flow Meter

Contains information on the principle of vortex flowmeter...

1. 1. What is Karman vortex?

The phenomenon of vortices behind pillars placed in the river was observed by Leonardo da Vinci in 1513. Then, in 1911, Theodore von Kalman first theoretically elucidated the formation of alternating, regular vortices downstream of an object placed in a fluid stream. This vortex street is called the Karman vortex street after his name.

The phenomenon of vortices behind pillars placed in the river was observed by Leonardo da Vinci in 1513. Then, in 1911, Theodore von Kalman first theoretically elucidated the formation of alternating, regular vortices downstream of an object placed in a fluid stream. This vortex street is called the Karman vortex street after his name.

In the natural world, "the wind blows the flag and the flag flutters", "the wind makes the electric wire growl", and "the aquatic plants on the stakes of the stream sway" are caused by this Karman vortex.

2. 1. Structure / principle of vortex flowmeter

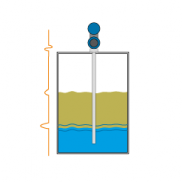

As shown in the figure above, the vortex flowmeter consists of a "vortex generator (bluff body)" that generates Karman vortices in the pipe, a sensor that detects the vortex, and a converter (amplifier) that processes the signal detected by the sensor. .. The above-mentioned Karman vortex is generated downstream of the vortex generator placed at right angles to the flow. It is known that the frequency at which this Karman vortex is generated is proportional to the speed (flow velocity) of the fluid flowing, and its relational expression is as follows.

![]()

Here, f is the vortex frequency, V is the average flow velocity of the fluid, d is the width of the vortex generator, and St is a constant called the Strouhal number. The Strouhal number changes depending on the Reynolds number (the number that determines the flow state), but it is almost constant over a wide Reynolds number range. Therefore, in the range where the Strouhal number is constant, the vortex frequency is proportional to the flow velocity, and as a result, the flow velocity in the pipe is known by detecting the vortex frequency, and finally by multiplying the flow velocity by the cross-sectional area of the pipe. Can calculate the flow rate (volumetric flow rate).

3. 1. Types of vortex detection methods

Many elements that detect vortices have been developed and put into practical use, and are used in fields that take advantage of their respective characteristics. The main detection elements and detection principles are shown in the table below. Currently, the piezoelectric element type, which has a simple structure, is highly durable, and is relatively inexpensive, is the mainstream.

4. 1. Shape of vortex generator

Since the shape of the vortex generator directly affects the performance of the flowmeter, various shapes have been put into practical use. An example of the shape of the vortex generator that has been put into practical use to date is shown on the right. You can see that there are many shapes with sharp edges in order to stabilize the separation point of the Karman vortex.

Since the shape of the vortex generator directly affects the performance of the flowmeter, various shapes have been put into practical use. An example of the shape of the vortex generator that has been put into practical use to date is shown on the right. You can see that there are many shapes with sharp edges in order to stabilize the separation point of the Karman vortex.

We have adopted a triangular prism (upper left in the figure on the right) for the shape of the vortex generator. The model name "Delta" was named because this triangular prism resembles the Greek letter Delta (Δ).

Nowadays, most manufacturers use trapezoidal or triangular vortex generators. Therefore, the National Institute of Advanced Industrial Science and Technology, the flow meter maker, and the user came together to determine the best-performing vortex generator by focusing on this shape, and a study group was born to provide it to the world. What was found from that was the shape of a standard vortex generator, which has the shape of a triangular prism (delta). Conversely, it can be said that the shape we have adopted has been authorized.

5. 1. Features of vortex flowmeter (summary)

Features of the vortex flowmeter

1. Simple structure and no mechanical moving parts

2. Great range ability

3. Applicable to a wide range of fluids (liquids, gases, vapors)

4. Good accuracy

5. Pressure loss is relatively small

6. For example, the amount of detection is digital (there is no effect on resolution)

. In addition, it is necessary to pay attention to the following points in the measurement principle of the vortex flowmeter.

1. 1. Affected by flow velocity distribution (requires some upstream straight pipe or rectifier)

2. If there is a pulsation, the vortex will be disturbed and a measurement error will occur, or the instruction will be hunted

. Vortic flow does not occur unless there is a certain amount of flow (small flow measurement is difficult. Problem of dead zone)

However, vortex flow meters that can easily and stably measure a wide variety of fluids with high accuracy will become more and more popular in the future. It is considered.

Share: